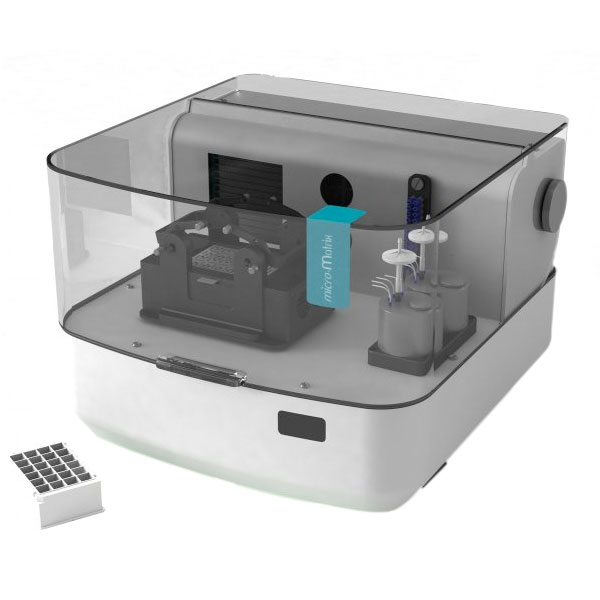

Sistema microMatrix

The unique micro-Matrix offers total control over 24 independent bioreactors in a simple microtiter plate footprint. Each of the 24 bioreactors on a plate offers independent controls like its larger stirred-tank relatives:

- pH (measurement and two-sided control, including plate-wide gradients)

- Temperature (measurement and two-sided control, including plate-wide gradients)

- Dissolved oxygen control (measurement and two-sided control, including plate-wide gradients)

- Individual liquid additions (including feeding profiles)

- Up to 4 separate gas additions (individually controlled)

The micro-Matrix is a true scale down of small-scale bioreactors. The bioreactor cassette design is based upon the popular SBS-format microtiter plates and seamlessly integrates into lab automation protocols. The square wells maximize mixing and optimize gas transfer. The PC-based human interface of the micro-Matrix offers simple, intuitive interaction with each of the 24 bioreactors. Integrated LEDs indicate the status of the bioreactors with color-based feedback so that operators can take in process information with one quick glance.

Features

- Independent gas supplies: for Air / O2 / N2 / CO2 / NH3.

- Integrated individual bioreactor liquid feed.

- Cascade up to five actuators per control loop per bioreactor.

- The control strategy is user definable per bioreactor per experiment.

- Individual temperature measurement and control per bioreactor.

- Individual pH measurement and control per bioreactor.

- Individual DO measurement and control per bioreactor.

- Orbital shaker 0-350 rpm @ 25 mm orbit.

Applications

- Screening of cell-line, microbial, and/or yeast libraries.

- Process development studies.

- Process optimization studies.

- Small volume cultivations.

Software

The micro-Matrix software offers an easy way to operate 24 bioreactors in parallel, as well as perform simple comparisons of large numbers of experimental cultures. Using an intuitive left-to-right progression, the interface guides operators through experimental setup, instrument configuration, control strategy definition, and data visualization. It is also possible to define time and event-based control actions. All data can be exported from the instrument during cultivation.

Measurement & control

Each bioreactor has its own PID controller for pH, dissolved oxygen, and temperature. Individual pH control can be achieved via gas addition, liquid addition, or a combination of both. Dissolved oxygen level can be individually controlled by up to four gas additions per bioreactor. Temperature can be individually controlled by the integrated cooling and heating system on a well-by-well basis, and users can define temperature gradients across the set of bioreactors.

Advanced control strategies are also available to users interested in cascade controls (up to 5 actuators per process variable), time-based setpoint changes, and event-triggered liquid feeds. Liquid feeding is also available using varying types of addition profiles.